Enhancing Item Development with Advanced Plastic Injection Molding Solutions

Enhancing Item Development with Advanced Plastic Injection Molding Solutions

Blog Article

Comprehending the Basics of Plastic Injection Molding Procedures

Plastic injection molding offers as a foundation of modern manufacturing, offering a systematic technique to generating intricate components with precision. Checking out these crucial components could expose exactly how even small adjustments can lead to substantial renovations in manufacturing results, raising inquiries concerning the possibility for advancement in this established procedure.

What Is Plastic Shot Molding?

Plastic shot molding is an extensively utilized manufacturing procedure that transforms polycarbonate and thermosetting products into accurate and complicated shapes. This technique is favored for its capacity to generate high volumes of the same get rid of exceptional precision, making it an essential method in numerous industries, consisting of automobile, durable goods, and clinical tools.

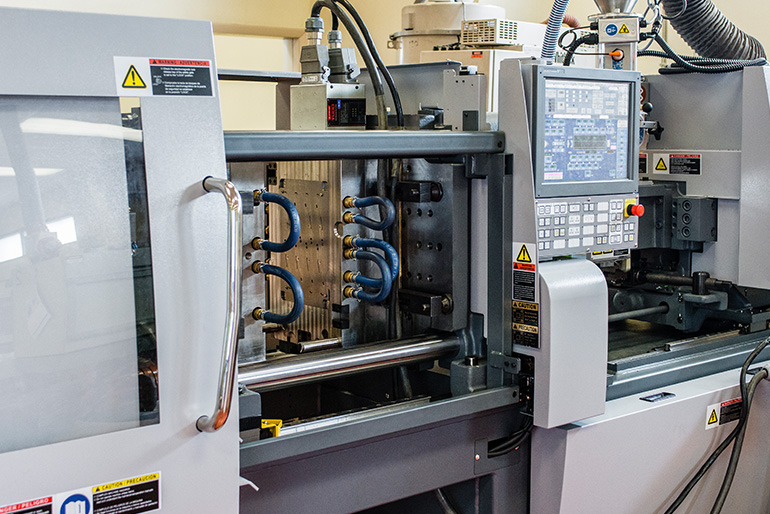

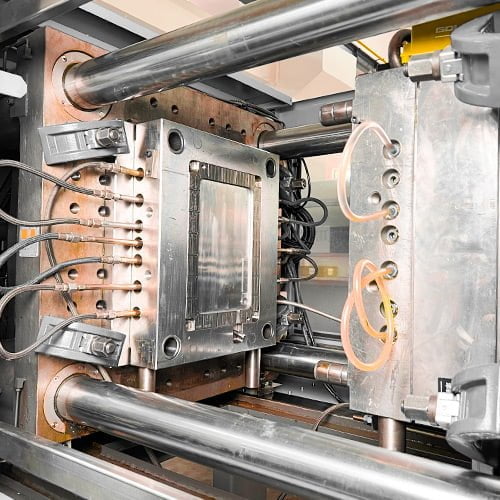

The process entails melting the chosen plastic material and injecting it right into a mold and mildew under high stress. The mold, made to the specs of the wanted component, permits the liquified plastic to take form as it solidifies and cools down. When the material has hardened, the mold and mildew is opened, and the completed element is expelled.

Plastic shot molding provides a number of advantages, including decreased waste, consistency in production, and the capability to integrate detailed layouts that might be challenging with various other manufacturing approaches. Furthermore, it sustains a wide array of materials, each giving distinct buildings that can be tailored for particular applications. As markets continue to introduce, plastic shot molding stays at the forefront, enabling the advancement of sophisticated products that fulfill advancing customer demands.

The Injection Molding Refine

The injection molding procedure is an advanced technique that includes a number of vital phases to generate high-quality plastic elements. Originally, plastic pellets are fed into a warmed barrel where they are merged a thick liquid. This molten plastic is after that infused under high stress into a precision-engineered mold and mildew, which forms the product into the desired kind.

When the mold and mildew is filled up, the plastic is permitted to strengthen and cool, taking the form of the mold and mildew tooth cavity. Air conditioning time is important, as it impacts the cycle time and the last residential or commercial properties of the molded part. After sufficient air conditioning, the mold opens, and the completed component is ejected making use of ejector pins.

Products Used in Injection Molding

Numerous products can be utilized in the shot molding process, each offering unique residential properties that provide to certain applications. The most commonly made use of products consist of thermoplastics, thermosetting plastics, and elastomers.

Thermosetting plastics, like epoxy and phenolic materials, go through a chemical change during the healing process, causing a stiff, stringent framework. These materials are optimal for applications calling for high warm resistance and architectural stability, often made use of in electrical insulators and auto components.

Elastomers, including silicone and rubber-based products, provide versatility and strength. Their distinct residential or commercial properties make them suitable for applications that require flexibility, such as gaskets and seals.

Additionally, specialized products like bio-based plastics and composites are obtaining traction for their environmental advantages and boosted performance qualities, expanding the scope of shot molding applications in different sectors. Recognizing the homes of these products is essential for selecting the ideal type for certain jobs.

Benefits of Shot Molding

Injection molding attracts attention as a very reliable manufacturing procedure that uses numerous advantages for producing complex components with accuracy. One of one of the most significant advantages is the capacity to create complex designs that would certainly be difficult or difficult to attain with various other techniques (Plastic Injection Molding). The procedure allows for link in-depth features and limited resistances, ensuring high-quality parts

In addition, injection molding is known for its quick production abilities, making it a suitable selection for high-volume manufacturing. As soon as the mold is created, parts can be produced quickly, reducing lead times and enhancing total performance. This effectiveness not only lowers production costs but likewise gives an one-upmanship out there.

The flexibility of materials made use of in injection molding even more improves its allure. A vast array of thermoplastics and thermosetting polymers can be employed, enabling suppliers to pick products that best satisfy their details demands, consisting of heat, flexibility, and strength resistance.

Furthermore, the procedure lessens waste, as excess product can frequently be reused and recycled. This sustainability aspect adds to a decreased environmental effect, making shot molding an accountable production option. In general, the advantages of shot molding make it a favored approach for many industries.

Factors Influencing Product High Quality

While various aspects can affect product high quality in injection molding, comprehending these components is essential for accomplishing optimum results. Secret elements include product selection, refining parameters, and mold and mildew layout.

Product selection plays an essential role, as various polymers exhibit special buildings that impact flowability, toughness, and thermal security. Insufficient product option can result in defects such as warping or incomplete dental filling.

Processing specifications, consisting of cycle, pressure, and temperature level time, must be meticulously managed. Variations in these setups can result in variances in component measurements and surface coating. As an example, exceedingly heats may create destruction of the polymer, while poor stress can lead to brief shots.

Mold and mildew design is equally crucial, as it identifies the flow of the molten plastic and the cooling procedure. Inadequately made molds might result in irregular air conditioning prices, causing dimensional mistakes and recurring stress and anxieties.

Final Thought

In final thought, plastic shot molding works as an important production procedure that allows the efficient manufacturing of top notch parts. Mastery of discover this info here the shot molding process, including the understanding of materials and the impact of different factors on item top quality, look at these guys is necessary for accomplishing optimum results. The benefits of this approach, such as cost-effectiveness and design versatility, further underscore its relevance across multiple sectors, strengthening its standing as a recommended choice for high-volume production.

Plastic injection molding serves as a foundation of contemporary production, giving a methodical technique to producing complicated components with precision.Plastic injection molding offers a number of advantages, consisting of lowered waste, uniformity in manufacturing, and the capability to incorporate complex styles that might be challenging with various other making approaches (Plastic Injection Molding). As markets continue to innovate, plastic injection molding continues to be at the leading edge, enabling the development of innovative items that satisfy advancing customer demands

The injection molding process is an innovative strategy that entails numerous vital stages to generate top quality plastic components.In final thought, plastic shot molding offers as an essential production process that allows the reliable manufacturing of high-grade parts.

Report this page